The Technology That Sets Rega Apart

Posted by The Sound Organisation on Oct 10th 2018

Low Mass, High Rigidity

While at times controversial, Rega has always designed turntables that emphasize light weight teamed with high strength. This method reduces resonance and improves sound quality, and can be seen in many of their products like the turntables and cartridges. Achieving this combination of low mass and high rigidity isn’t easy, necessitating high tech materials and manufacturing techniques, many only available at these prices because of Rega’s ability to scale production. From the stressed skin RP1 to the nitrogen-foamed polyolefin RP10, these bantamweights hit hard.

While at times controversial, Rega has always designed turntables that emphasize light weight teamed with high strength. This method reduces resonance and improves sound quality, and can be seen in many of their products like the turntables and cartridges. Achieving this combination of low mass and high rigidity isn’t easy, necessitating high tech materials and manufacturing techniques, many only available at these prices because of Rega’s ability to scale production. From the stressed skin RP1 to the nitrogen-foamed polyolefin RP10, these bantamweights hit hard.

Tapered Arm Wand

The tonearm is where all the heavy lifting is done, and the arm wand is often times the weakest link in this system. Rega uses a gently tapered one piece arm that was profiled using advanced 3D modeling, and has won several awards in the manufacturing world for its unique design and implementation. This design allows Rega’s engineers to optimize its weight balance, tipping the heavier end towards the pivot point where it belongs. Most importantly, conical shapes naturally reduce resonance and redirect unwanted energy away from the sensitive cartridge hanging from its tip.

The tonearm is where all the heavy lifting is done, and the arm wand is often times the weakest link in this system. Rega uses a gently tapered one piece arm that was profiled using advanced 3D modeling, and has won several awards in the manufacturing world for its unique design and implementation. This design allows Rega’s engineers to optimize its weight balance, tipping the heavier end towards the pivot point where it belongs. Most importantly, conical shapes naturally reduce resonance and redirect unwanted energy away from the sensitive cartridge hanging from its tip.

Stressed Skin Structure

Intrinsic to the low mass design ethos of Rega turntables, stressed skin design allow their engineers to use lightweight materials like foam or fiber board. The skin itself is either laminated phenolic or sprayed acrylic, that once bonded to the core material increases stiffness and strength and drops resonance. These are not thin coatings, as is seen if you look at the plinth cross section of RP6 or RP8. The same technology is used for the wings of jet aircraft and other designs that require both light weight and strength.

Intrinsic to the low mass design ethos of Rega turntables, stressed skin design allow their engineers to use lightweight materials like foam or fiber board. The skin itself is either laminated phenolic or sprayed acrylic, that once bonded to the core material increases stiffness and strength and drops resonance. These are not thin coatings, as is seen if you look at the plinth cross section of RP6 or RP8. The same technology is used for the wings of jet aircraft and other designs that require both light weight and strength.

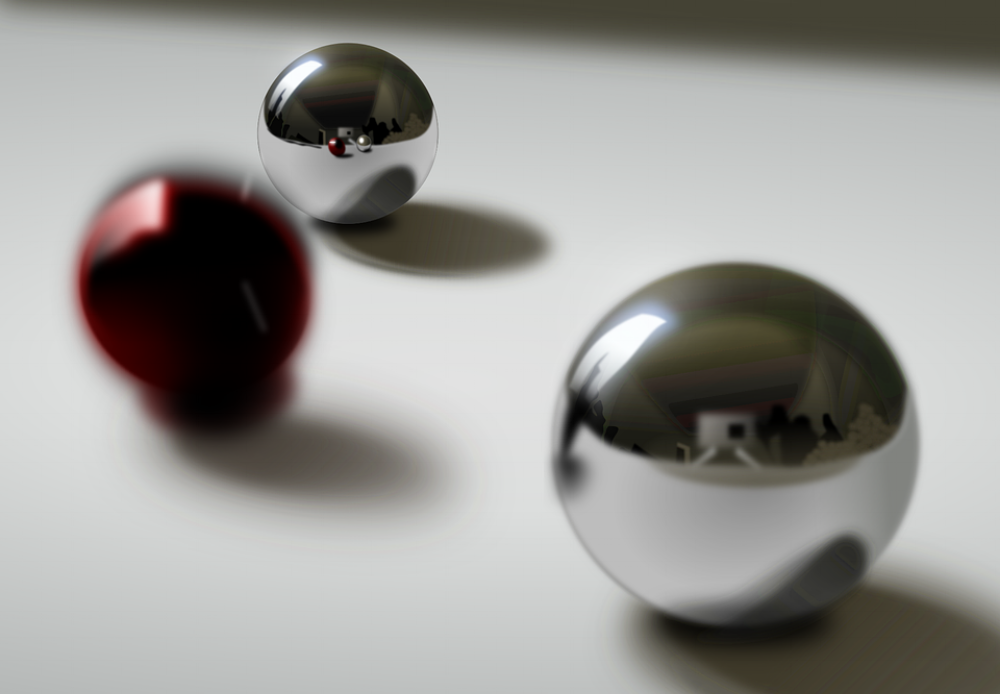

High Tech Platters

Whether ceramic, glass, or phenolic, Rega has always applied a great deal of engineering know-how into its platters. Deceptively simple, the platter is critical to the sound of a turntable. All Rega platters are focus on low resonance, balance and stability. Phenolic is used in the basic tables because of its natural balance, non-conductivity and very low audible resonance. Glass is used in step up models for its greater stability and smooth surfaces. Applied in multiple layers, glass has even greater speed stability created by the "flywheel effect". The very best tables use ceramic oxide, because of its ultimate stiffness and extreme resonance control.

Internal Grounding

Unlike many manufacturers that require you to establish a proper ground for your turntable, Rega has taken the fuss out of setup. Simply connect the standard RCA leads from your turntable to phono preamp, and you are good to go. This brilliant scheme drops background noise, and works perfectly for the vast majority of HiFi systems. If you need an alternative, there are plenty of options. See your handy local Rega dealer for help.

Hand Matched Bearings

Bearing quality and fitment is an area the Rega has unique experience in, starting with its very first turntable in 1973. Each and every bearing is hand-graded to ensure maximum quality. Fitting the bearing to its mate is the next step, as the individual quality matters not if it doesn’t work well as an assembly. This approach is unique at this end of manufacturing, as its usually only done in very high end. The sound quality improvement is notable, making Rega tonearms top of the heap and well worth the effort. Yet another reason why Rega 'tables are of such extraordinary value.

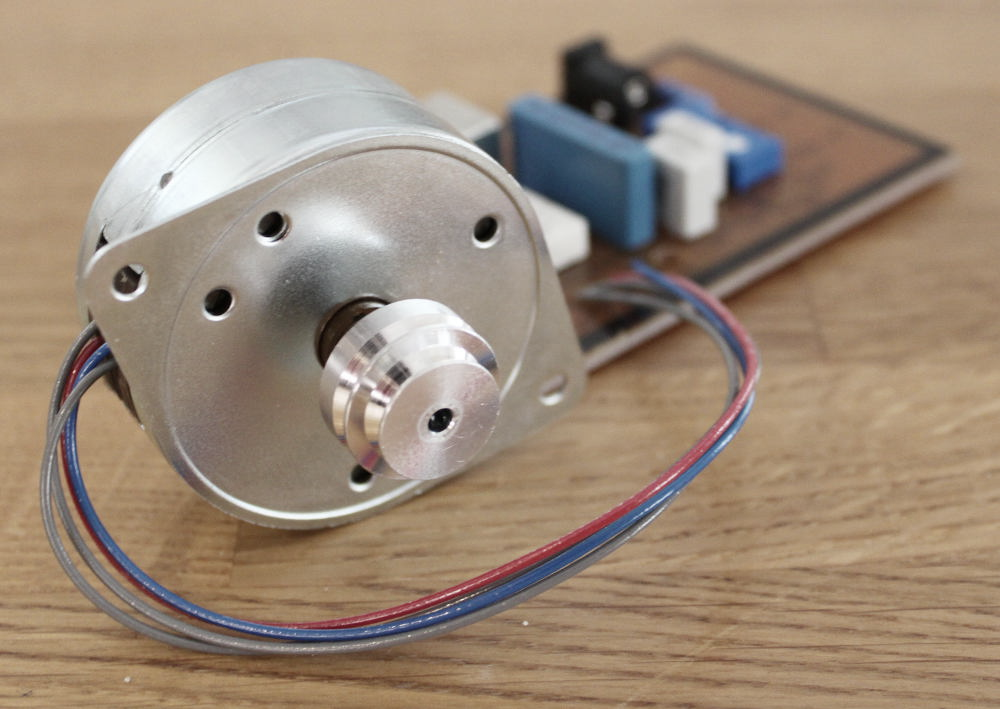

Low Noise Motors

All motors produce some kind of noise, whether audible vibration or electrical radiation. Even though small, these noises can be easily picked by the tonearm and cartridge. Rega uses low torque motors that produce a minimum of vibration, often twin-phase 24V shielded units. Some tables include, or can be upgraded with the TTPSU. This clever device tunes the motor to reduce vibration to essentially zero, and radically improves speed consistency.

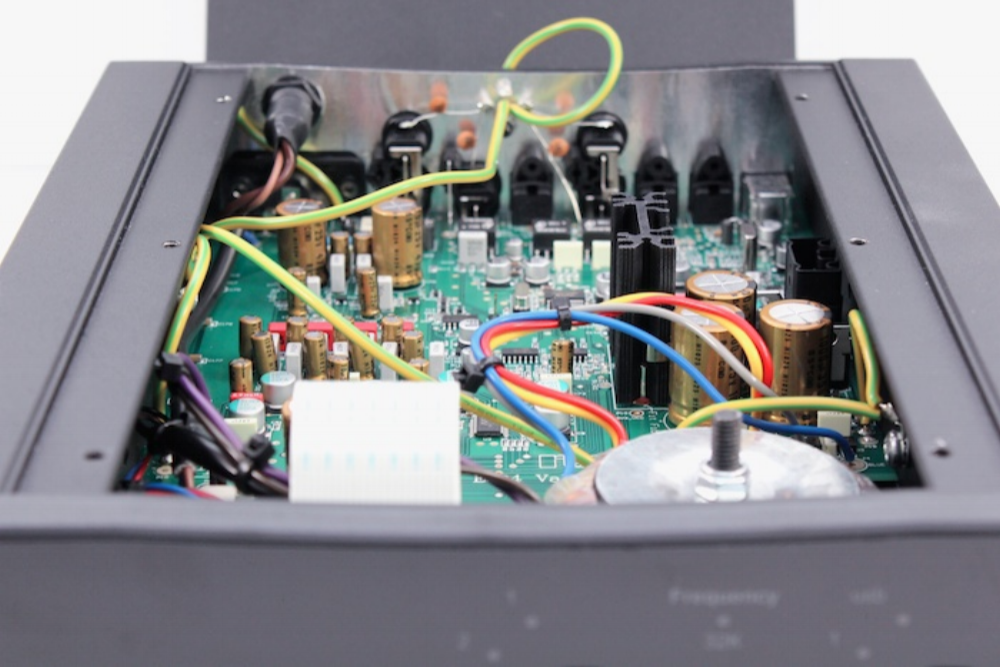

Toroidal Transformers

The average transformer is bulky, inefficient and noisy. Toroidal transformers are elegant, efficient and especially quiet. Crucial to the final performance of any audio device, Rega uses toroidal transformers almost exclusively. Where they can’t use them, the power supplies are kept outside of the main case. Clever.

Custom Disc Mechanisms

The weak point in most CD player designs, the disc "tray" decreases sound quality and reliability because of its mechanical instability. For this reason, Rega has always used top-loading mechanisms that eliminate the more commonly used tray. The top-loading mech is controlled by custom written software developed by Rega that improves playback by reading ahead and selecting the proper method for playback and correcting for flaws.

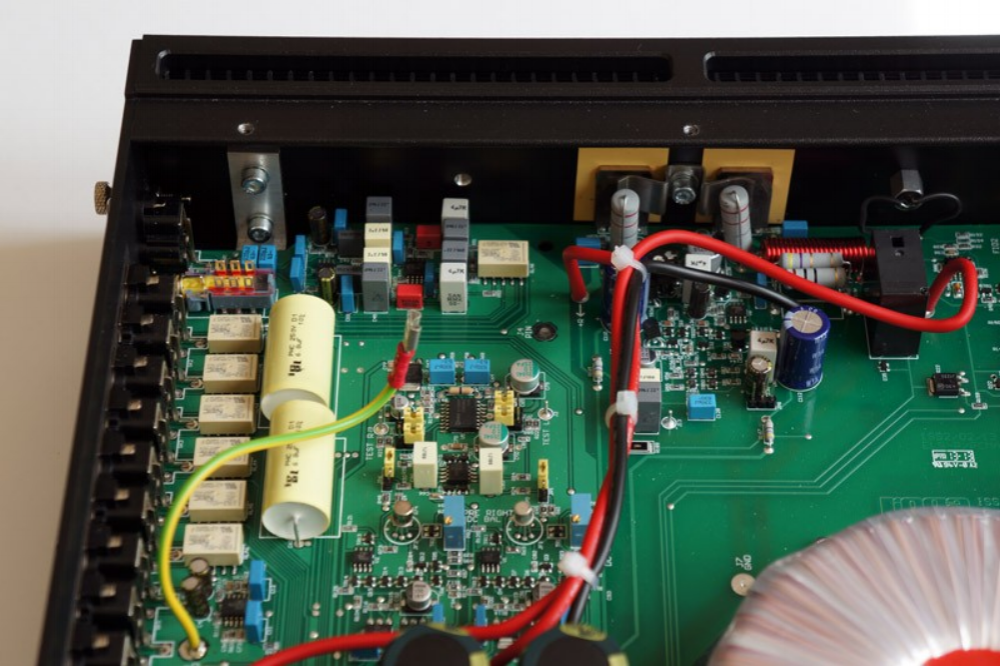

Discrete Components

Whenever possible, Rega eliminates op-amps and other ICs in critical audio pathways. These pesky little devices are very noisy and don’t deliver the best performance. Instead, they prefer discrete components which always live up to the task and deliver the highest sound quality. They cost more and they take up more space, but are so, so worth it.

Optimized DACs

Rega has a close relationship with Wolfson, and has used that to their benefit in extracting the maximum amount of performance from their DAC chipsets. Great lengths have been taken to reduce noise in circuits, and provide the best possible environment for the chips to operate in. Custom dedicated power supplies for each digital, analog and control sub-systems ensures to cross contamination and delivers wide dynamics. Galvanically isolated inputs and bit-perfect asynchronous USB reduces negative interaction with source devices. Advanced buffers and filters, audio-grade components throughout, and unique clocking that reduces jitter, makes for the smooth, high resolution and analog-like playback you’d expect from Rega.